Rice Rubber Rolls

Rice Rubber Rolls

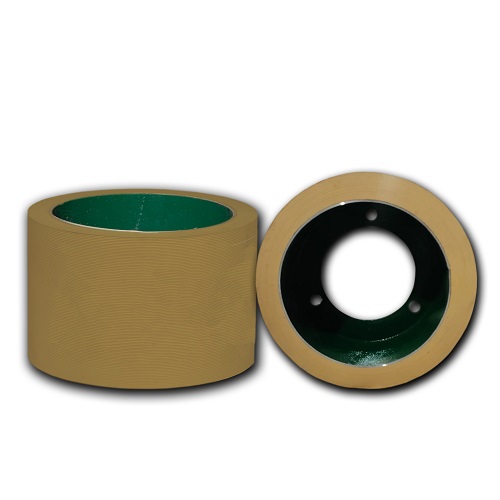

We offer specially crafted, top-notch Paddy De-Husking Rice Rubber rollers to get the most milled rice out of the paddy with the least amount of breakage.

Rice Rubber Rolls

Rice Rubber Roller is a spare part for the rice huller machine. The rice huller machine can operate continuously at high hulling rates for 24 hours non-stop thanks to its superior abrasion resistance.

In order to separate the rice husk from the grain, rice mills use rice rubber rollers. Rice Rubber Rolls have a significant impact on the rice production businesses.

Functioning

Two identically sized rollers are linked in a rice mill huller roller. They run at various speeds, though. One of the rollers’ positions is set. Additionally, based on the desired clearance, the location of the other roller is adjusted.

Comparatively speaking to the fixed roller operating at a faster speed, the roller that is modified (for each milling cycle) must run more slowly. To remove the brown rice hulls from the grain, an aspirator is affixed to the machine’s base. When rice is hulled (dehusked), the rice hull is removed from the paddy grain to create brown rice which then goes into further processing.

Types

To get the most milled rice out of the paddy with the least amount of breakage, we provide different sizes of high-quality Paddy De-Husking Rice Rubber rolls.

Rubber Roll 6″

Three variants of this sort of rubber hulling roll are available:

Flange Type

These rubber rolls for rice hulling are typically made of aluminium and have a flange in the centre of the drum.

Plain Type

Old-style plain rolls with a wire netting base are pinned to a cylinder by rubber.

Key Type

The key is in the centre of Key Type rolls, which are rubber-stacked on the cylinder.

Specification

Length: 152mm + – 1mm

Rubber Thickness: 28-29mm

Outer Diameter: 224mm + – 1mm

Rubber Roll 10″

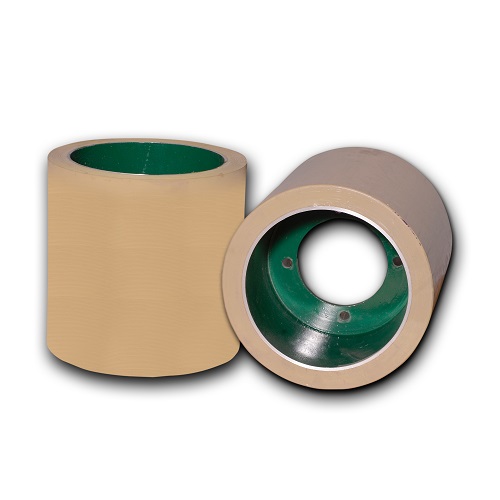

The best-selling model of rubber rolls for rice mills worldwide is now this type. Cast iron, mild steel, and popular model aluminium drums are used to make these rolls drums. In most of the rice mills 10″ Aluminium rubber roll is used as it gives more output.

The flame on these rolls is located in the centre of the drum. When compared to drums sold in the market, the aluminium drum we make at home is far stronger.

We are producing two types of rubber rolls depending on its thickness:

1. Jumbo, 30 mm

2. Standard, 25mm

Specification

Length: 254mm + – 1mm

Outer Diameter: 254mm + – 1mm

Rubber Roll 12″

The 12′′ Rice Huller Rubber Roller is the newest invention, and this style of rice hulling rollers is expanding its market share every day. These rubber rolls for hulling rice are typically made of aluminium and have a flange in the centre of the drum.

These Rice Husker Rubber Rolls come in two varieties:

Raw Boiled Paddy

Parboiled Paddy

Specification

Length: 305mm + – 1mm

Rubber Thickness: 25mm + – 1mm

Outer Diameter: 254mm + – 1mm

Rubber Roll 14″

Two types of 14″ rice mill rubber roller are available.

One model is often made of iron, has flanges on both sides of the drum, and is an exact replica of the 20′′ model with the exception of length. Another model is identical to the most popular model, which is 10′′ in diameter and features a flange in the centre of the drum. Iron and aluminium are typically used to make this sort of drum.

These Rice Husker Rubber Rolls come in two varieties:

Raw Boiled Paddy

Parboiled Paddy

Specification

Length: 355mm + – 1mm

Rubber Thickness: 25mm + – 1mm

Outer Diameter: 230mm + – 1mm

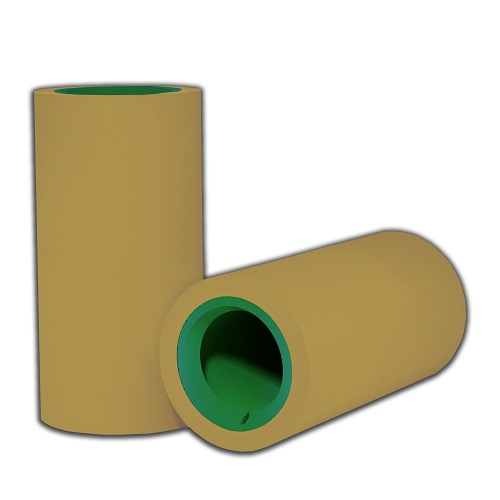

Rubber Roll 20″

This is the largest size Rubber Roll Sheller that has ever been used in a rice mill as rolls to dehusk paddy. These rice mill huller rollers’ drum is composed of cast iron, which makes it heavy. This type of device is quite challenging to make on an aluminium sleeve because of the flanges on both sides. Because of its enormous milling capacity and sheer size, this type of roll is perfect.

These Rice Husker Rubber Rolls come in two varieties:

Raw Boiled Paddy

Parboiled Paddy

Specification

Length: 508mm + – 1mm

Rubber Thickness: 25mm + – 1mm

Outer Diameter: 254mm + – 1mm

Advantages

- Adequate Resiliency

- Well-balanced hardness

- Great resistance to wear

- Maximum hulling rate and capacity

- Lowest breaking rate

- Climate Resistance

- Heat Resistant

- Opt for each variety of paddy produced in the world

Points To Remember

- Standard hardness of the rolls is 92-95 but if someone needs 88 hardness or any hardness ranging from 88-95 we will provide them. But hardness of the roll depend on type of rice mill.

- Average Running time is not fixed and no output is quoted by our company. It all depends on rice plant i.e what kind of mill it is, what kind of machinery people are using & what kind of rice is being produced. But we can say on an average average running time is:

- Raw Rice (Short Grain): 175 tonne

- Raw Rice (Long Grain-Basmati): 150 tonne

- Parboiled Rice: 300 tonne

- Standard Thickness of the roll is 25mm but we can provide thickness according to the buyer’s requirement but with increase in thickness price will also increase.

error: Content is protected !!