Nylon Core Belting

Nylon Core Belting

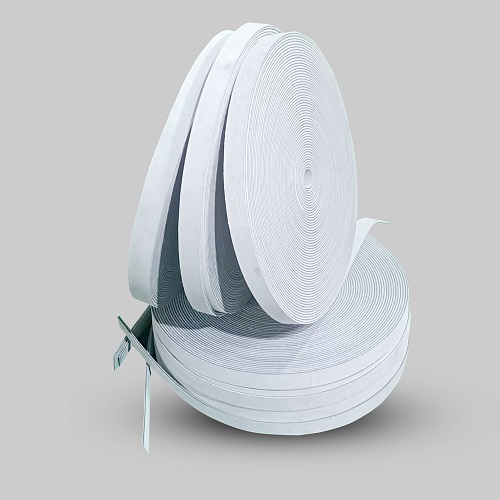

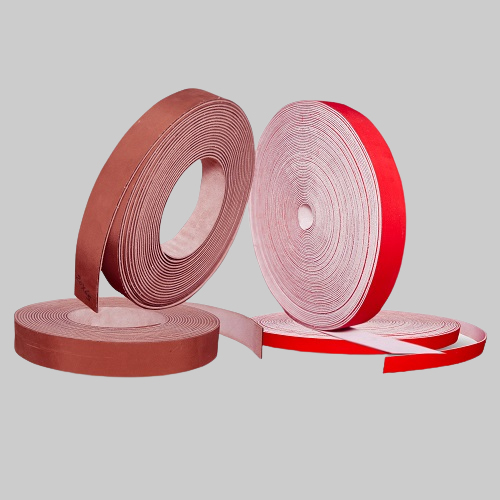

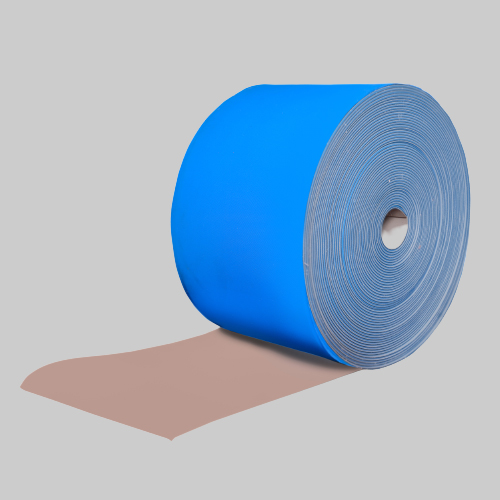

We provide belts of the highest quality, which are fastened in conveyors in enterprises all over the world. Friction coverings composed of synthetic rubber, chrome leather, nylon fabric, or other combinations are laminated on both sides of these.

Nylon Core Belting

Our high-efficiency polyamide flat belts have a traction layer consisting of HIGHLY ORIENTED POLYAMIDE that cushions the pressures placed on the belt during power transmission. The frictional cover (CHROME LEATHER/ELESTOMER-NBR/NYLON FABRIC) ensures that the belt and pulley are transferring power to one another.

Features

- High Flexibility

- Low Power Consumption for Machines

- More Shock Absorbing Power

- Very Low Maintenance Cost

- Long Life Durability

- Proven Durability in Intense Industrial Operations

- High Friction Levels

- Low Weight

- Less Pressure on Machines

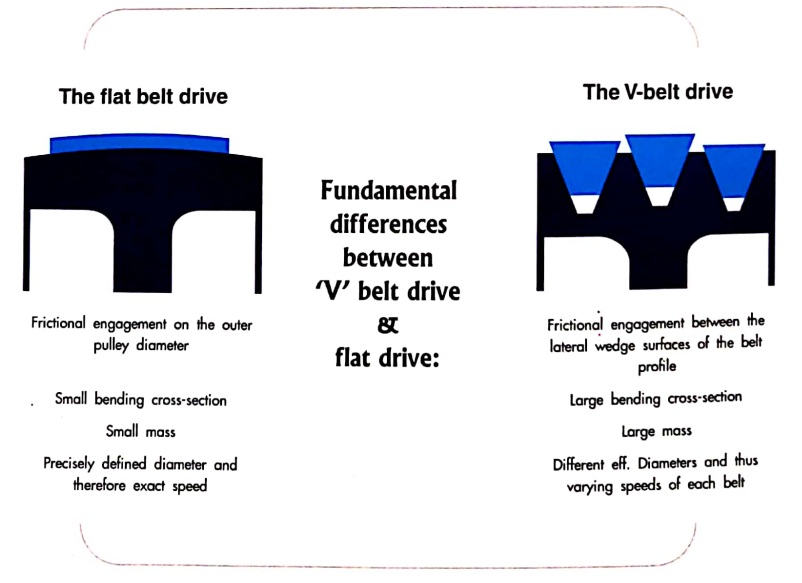

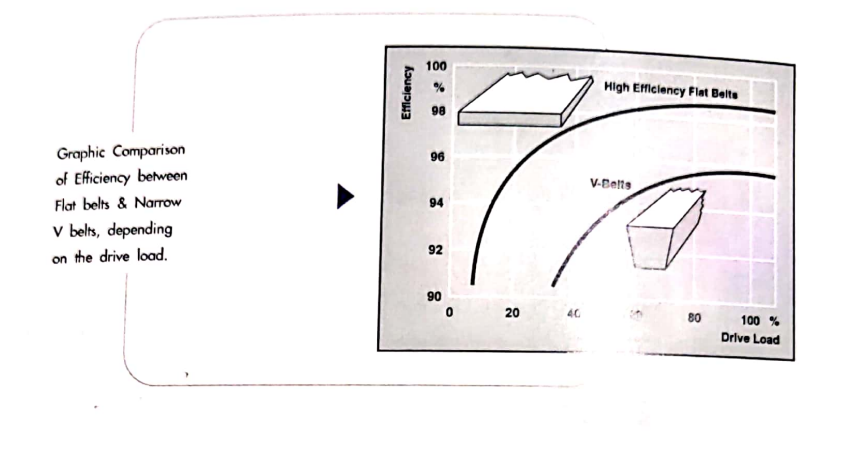

Diagrams

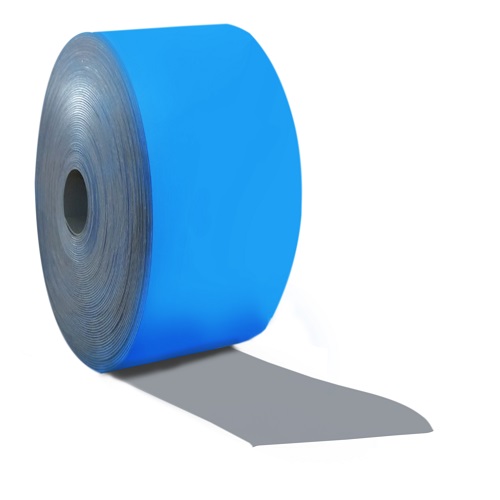

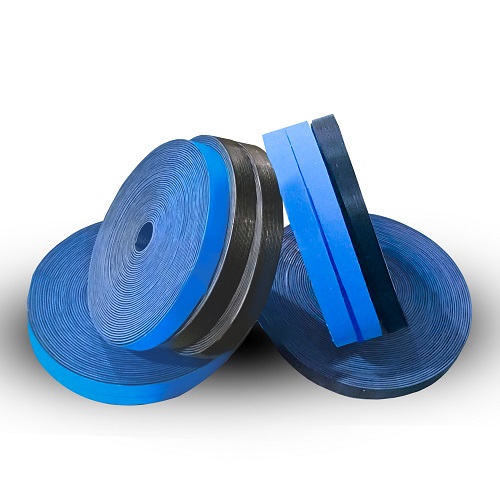

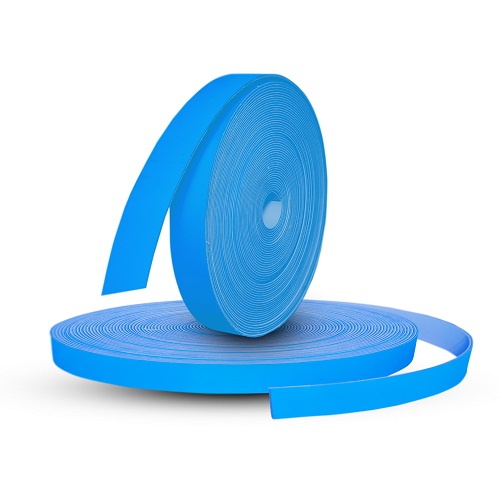

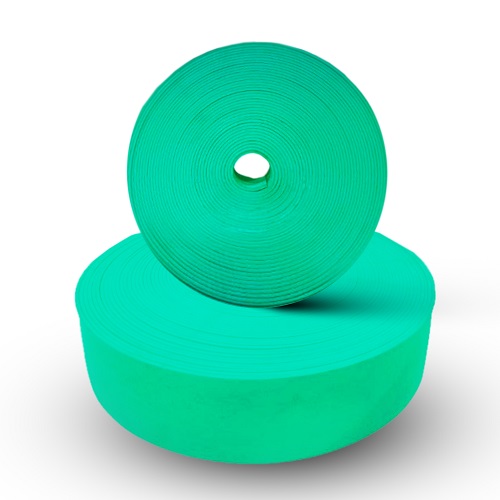

Our Range of Belts

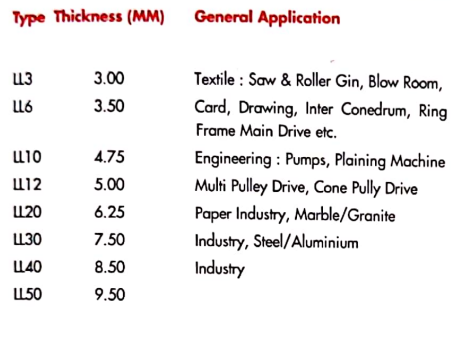

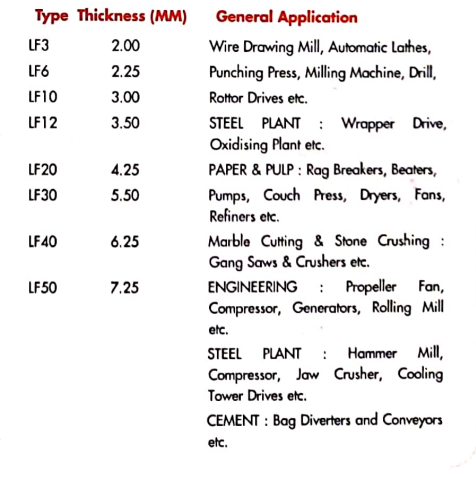

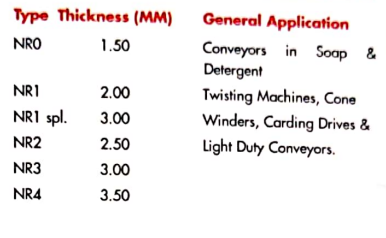

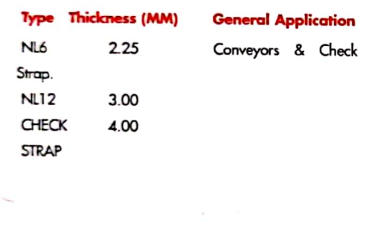

Specification

Our modernized nylon sandwich belts use less energy than others and operate without interruption for extended periods of time. Since the quality of the belts is our first priority, we only use premium raw materials. Our belts are renowned for their strong heat resistance and low speed fluctuation. High-quality chrome leather frictions are the foundation of our leather Nylon Sandwich Beltings, which are covered with polyamide sheet. Furthermore, our belts are more effective thanks to their great flexibility and increased shock absorption. In addition, our nylon sandwich belts are extremely durable and require very little upkeep. Due to their great resilience, these belts are able to transport big weights from one end to the other in a variety of industries

error: Content is protected !!